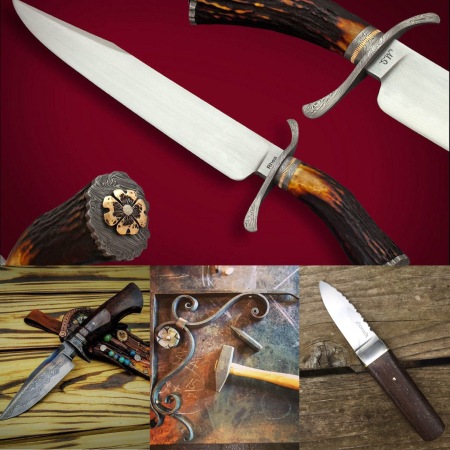

Here are the last two knives I finished:

Archive for the Forging Category

Scagel Inspired Hunting knife

Posted in Blacksmithing, bladesmithing, brutdeforge, Forging, knifemaking, Leather working, metalwork with tags Brute de forge, custom knife, hunting knife, Scagel on January 2, 2019 by JimCustom Hunting Knife

Posted in Blacksmithing, bladesmithing, Forging, knifemaking, metalwork, Tool Making with tags Camping, custom knife, edc, forged, hunting knife, Knife on July 20, 2018 by JimA little hunter I just finished up with some progress pics. It is 1084 steel with a stabilized box elder burl handle and a brass guard.

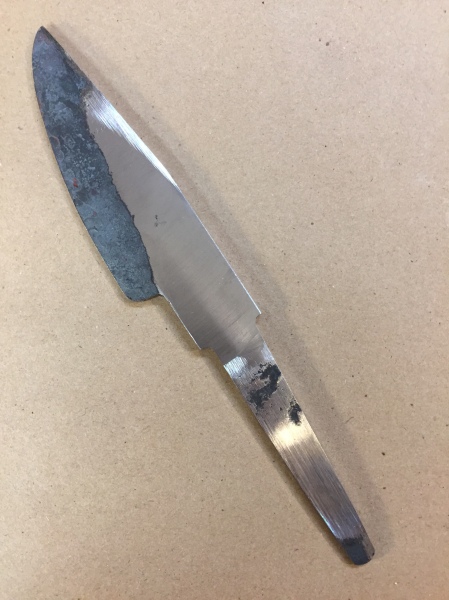

Just off the anvil.

Forging done and profiled.

Ricasso flattened in preparation for laying out for grinding and for fitting the guard.

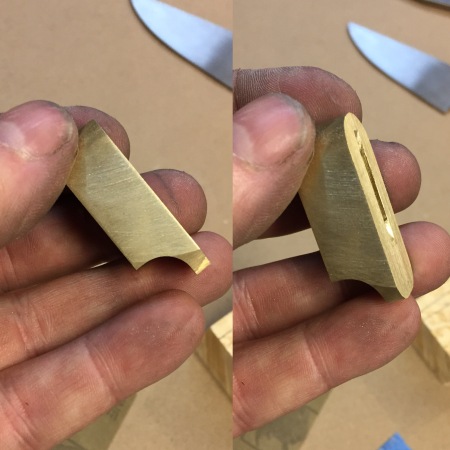

Starting to fit the brass guard with a guard press.

The guard slotted and rough shaped.

Laying out the blade on the handle material.

Thanks for looking – happy making,

Jim

Instagram hammer-in August 26th!

Posted in Blacksmithing, bladesmithing, Forging, knifemaking, metalwork, Tool Making with tags blacksmithing, bladesmithing, Forging, instagramhammerin, knifemaking on August 23, 2017 by Jim

Saturday August 26th, 2017 (1pm CDT) – four of us are going to do an Instagram hammer-in (#instagramhammerin) for you all to watch. We will each forge a knife of our own design, starting with the same sized stock, forge for two hours, and show a picture of the blade every 10 minutes or so.

There will be four smiths working ABS Mastersmith Lin Rhea, Forged in Fire contestant Robert Burns (Wilderness Ironworks) , blacksmith instructor Matt Jenikns (Cloverdale Forge), and me.

This is not a contest. No prizes will be awarded – it’s just for fun and hopefully the pictures will be an educational resource for new bladesmiths.

We hope you follow along, ask questions, and enjoy these great smiths (and me) showing us their forging step by step. Follow along by watching the hashtag #instagramhammerin

Forging a bottle opener from a bolt

Posted in Blacksmithing, bottle opener, EDC, Forging, Gear Making, metalwork, Tool Making with tags blacksmithing, bottle opener, edc, Forging, forging a bottle opener from a bolt, make stuff with your hands, makestuffwithyourhands, recycling on June 10, 2017 by JimI posted a video on YouTube showing how I forge one of my large bolt bottle openers.

Thanks for stopping by,

Jim

Loveless Style Hunting Knife in O1

Posted in Blacksmithing, EDC, Forging, knifemaking, Leather working, metalwork, Tool Making with tags 01 steel, edc, handmade knife, hunting knife, loveless bolts, loveless drop point, micarta, pocket knife on January 7, 2014 by JimI started this knife quite a while ago. It has been sitting on my bench for over a year – until now.

I made it to be part of a hunting set and showed the smaller first knife here quite a while ago.

Here are the two knives finally together.

I carry the smaller knife as a fixed blade edc pocket knife.

They are both 01 steel with green micarta handles and red liners. The blade on the larger one is about 3″.

I also made the sheath and to be honest – I almost enjoyed that as much as making the knife.

Happy Making and new year to you,

Jim

Integral Knife forged from 52100

Posted in Blacksmithing, Forging, knifemaking, metalwork, Tool Making with tags 52100, blacksmithing, bladesmithing, hand forged knife, stag handle on November 4, 2013 by JimI recently got a beautiful integral fixed blade knife from Master Smith Ray Kirk. I like it so much that I had to try and make one for myself. I bought a couple 3/8″ round bars of the 52100 from Ray and here is what I came up with:

Thanks to my friend Dave from Circle H forge for the beautiful piece of stag.

Lots of folks have been helping me with all this. Ray spent an hour walking me through how to make a blade like this.

Also, Master Smith Lin Rhea is always there with an answer to anything I need help with.

I have come to find that the folks in the American Bladesmith Society are just some of the best people out there.

-Happy Making,

Jim

Oh Happy Dagger…

Posted in Blacksmithing, Forging, knifemaking, metalwork with tags dagger, knifemaking on July 26, 2011 by JimMaking a dagger from a file.

A friend had this blank for years. It was started by his pal. He told me that he wanted to make or have it made into a finished dagger so he can return it to its original creator as a surprise. Maybe there is a little romance in the fact that he has carried it around all this time. I get sentimentally attached to objects myself, so this project interested me.

I’m all in when I think there is a little history or romance in a project. I spent a little quiet time with it last night and here is where we got:

The blank was still hard as diamonds when I got it, so it went in the forge and got annealed. After, I ground the sides flat just enough to put the purple layout dye on it, scribe a center line, and begin to layout the tang.

More to come soon as I can get back into the shop.

Happy Making,

Jim

Blacksmithing, knifemaking, and knife filework

Posted in Blacksmithing, Forging, Gear Making, Hammers, knifemaking, metalwork, Tool Making, Uncategorized on August 30, 2010 by JimIt was a busy weekend.

I spent a lot of the weekend painting the house but somehow still managed to sneak in forging a new knife. I have made several stock reduction (grind away everything but a knife) knives. I wanted to try making one mostly in the forge.

This is the knife sitting on a piece of the spring that it was made of. In this picture, the knife is shaped but not yet hardened and tempered.

Here is the knife completed. I hardened and tempered it then blued the entire thing with gun blue. I wanted it to keep that blackish look it has right out of the quenching oil.

It’s not a fun project if it doesn’t require making a new tool…

I wanted the knife to look like the steel had been lying on an abandoned barn floor in Montana for 50 years. Unfortunately, the blank my friend roughed out from the spring was smooth and straight. A few minutes with a fifty cent garage sale hammer and a welder came up with this texturing hammer:

Here is a detail of the ‘rustic’ area of the knife…

Here is a closeup of the file work on the spine. I tried to stay pretty simple in accordance with the rustic style of the knife:

This was a great project and I learned a ton. My blacksmith friend is teaching me more bit by bit. I am trying hard to soak it all in.

I hope you had a great weekend.

Go make something,

Jim

More hammered jewelry

Posted in Forging, jewelry, jewelry making, metalwork, Raising Copper on August 16, 2010 by JimMaking jewelry is more fun than I want to admit

I am still fooling around with making small jewelry pieces. This really is more fun that I am letting on and less messy than making a coal fire in the forge.

A tale of two rings

I made the silver and copper ring in this photo by punching out a half inch hole in the center of a quarter. I rolled it into a ring on a mandrel. This style is called a ‘washer ring’. There is a great video about doing this with Mokume Gane (silver and copper layered like damascus steel) on youtube here. The second, and larger, ring in this photo is formed from hammered copper wire. I soldered it with silver solder and it has a visible solder line. It also turns your finger a pretty shade of green…

If any of the folklore about copper is true, I will never have any arthritis pain.

I also made another set of earrings. This time I branched out and added some red stones to the center of the flowers. I am getting plenty of flack from the guys for all this by the way. I guess I will just have to buck up and take it.

I put the earrings up for sale on my newer Etsy site here.

Alright, enough reading, get up and go make some stuff!

Have a great week,

Jim

Hammered Copper Earrings with copper flowers

Posted in Forging, jewelry, metalwork, Raising Copper on August 4, 2010 by JimTiny hands would be very helpful if you were a jeweler!

My hands were not made for this tiny stuff but I was coerced.

A friend saw my hammered copper fishing lure from the post just before this one. She asked me to make her a pair of copper earrings. She has a look that says ‘You damned well better do this,’ and ‘pretty pretty please’ at the same time…

All that is left to do is drill the holes for the part that goes through your ear.

If there are any jewelers looking at this – give me a break. I am more of a ham-fist, better suited for blacksmithing and making fishing lures than jewelry. I am impressed with all you folks that can make tiny things.

Happy Making,

Jim