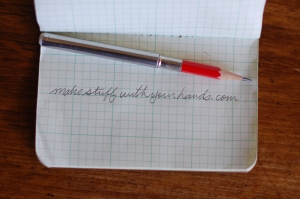

I love advertising pencils

The ones that say ‘Dot’s Diner 123 main,’ etc… If I see them in a box at an auction or rummage sale, they are coming home with me. My problem with them is that the erasers are rock hard and sometimes the pencil tube is cracked or broken somehow. Usually, they are simply constructed – a tube with an eraser in one end and a steel cap that holds a pencil to put in the other. The pointy cap bit is difficult to make, so we won’t do that.

But first – you can rehab an existing pocket pencil

If you don’t want to go through all the hassle of making you from scratch, you can fix up an old one that is in decent shape. On the vintage pencils I have, the erasers are mostly the same size as newer children’s pencil erasers.

I found a bin full of these Musgrave TRY-REX pencils at a local office supply and I just yank the eraser from the Musgrave and replace the rock hard one in my pocket pencil. I also shine up the caps on my pocket pencils with SimiChrome polish on a soft rag – only a tiny bit of polish is needed. It is foul smelling stuff but does a great job.

If you are feeling more adventurous, you can make a new pocket pencil (with a little stealing…)

You will need an existing vintage pencil for this. Find the nastiest cheap one that still has a good chrome cap on it. That is the only part we need. Take the chrome bullet end off and head to the hardware store. Looking at my local hardware store yielded this 3/8″ x .028″ stainless steel tubing.

Use the chrome end off of your old pencil and try to gently press fit it into tubing at the store until you find a piece that is just a hair too tight. If it is too loose, it will not work.

I use this slotted mandrel from Rio Grande that lets me put my own sandpaper bits in my Dremel or flex-shaft. I needed to remove quite a bit so I started with 80 grit, and I worked my way down to 400 grit, constantly testing with the cap from the old pencil, until it just goes in easy enough. Sand a little, test fit, sand a little more, test fit… For the eraser on this one, I found some Retro 51 Big Shot eraser replacements that fit with just a little polishing inside the stainless tube. The Musgrave ones would work, but I liked the look of the white eraser with the stainless tubing. Cut the last few inches off of your Palomino Blackwing pencil (or steal a golf pencil from the library like I did), put it in the chrome cap, and there you have a life-timer of a pocket pencil!

(Click the picture for a larger view) Happy Making, Jim