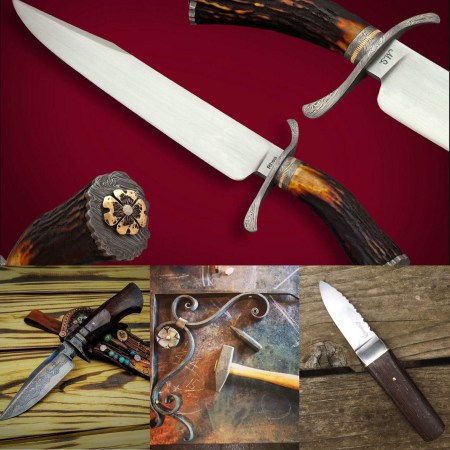

Here are the last two knives I finished:

Drop Point Hunter Knife Pattern

Posted in knifemaking, Tool Making, Woodworking on December 2, 2015 by JimNo tutorial today, but process pics.

I am working on a drop point hunting knife and was not sure from my sketches if it was going to feel how I wanted. I needed to hold it.

I ground the blade just as if it was steel – but it is cherry. I also roughed in the guard and handle in walnut.

Here it is with the ‘blade’ glued in and the handle shaped.

It might seem silly to rough it out all in wood – but holding it in my hand told me what I needed to know. If all goes well, I will post pics of the real knife soon. This one is a drag to keep sharp…

Happy Making,

Jim

Lets make a wooden fishing lure

Posted in Fishing, Fishing Lures, Wood Carving, Woodworking with tags fishing lure, handmade fishing lures, handmade wooden fishing lure, lure making on March 10, 2014 by JimSummer fishing season is Coming!

I am bringing this post over from an older blog of mine because it is time! Today, it is warm here – windows open short sleeves warm – so here you go:

I remember digging in my uncle Doug’s tackle box as a kid and being mesmerized. I was none too fond of the smell of his catfish bait. It was home made stuff – imagine fish kimchee in a mason jar… Regardless, I love the look of wooden fishing lures. It is possible (and pretty fun) to make a few simple lures on your own without any expensive tools.

You will need:

- A 5/8″ dowel from the hardware store

- The smallest screw eyes you can find, also from the hardware store

- Sandpaper (60, 100, 150 grits or close would be fine)

- A wood rasp can also help speed up the shaping

- Paint of your choice (I like the inexpensive acrylic stuff from Hobby Lobby)

- An awl or sharp nail to poke starter holes

- Some split rings and fishing hooks from a sporting goods store

- A saw that will cut through a small wooden dowel

Lets get started. First, measure off a 3″ piece of your dowel and cut it off.

Not too hard so far… Next, put a pencil mark in the center of both ends the ends of the dowel, and poke starter holes there.

Put a screw eye into the holes in each end.

Next comes the shaping. Take the screw eyes back out, lay the 60 or 80 grit sandpaper on a flat surface, and drag the dowel toward you while slowly lifting the back end up. Rotate the dowel a bit and continue. The idea is just to round over the dowel until it looks like a cigar. You can speed this up with a wood rasp if you can lay hands on one.

After you have the ends of the dowel roughly rounded, pick it up, grab your sandpaper and get the rough off. If you want, you can sand it entirely smooth, or you can just sand a little bit. I am pretty sure that the fish care do not care how beautiful your lure is. Use the finer sandpapers until you have the lure as smooth as you would like.

Here are two lures; the one from the pictures above and another that I sanded into a different pointier shape.

I have the lures hanging from a coat hanger that I cut in two and bent up. This holds them nicely while you spray primer on them. If you don’t want the fumes, you certainly do not have to use spray paint. I do, just to speed things up. Whatever paint you use, read and follow all the safety instructions…

I wanted my cigar shaped lure to have a fish scale pattern, so I wrapped it with tulle fabric. Tulle is what you make butterfly nets out of when you are little. I got mine at Hobby Lobby.

I hold the lure by one of the screw eyes with a clamp or some pliers. Next, I lightly spray paint the lure over the mesh. After the paint dries, you get a scale effect.

One other traditional way to paint lures is all white with a red head. The trick to getting the straight line on the red is by dipping instead of brushing or painting. First paint your lure all white. I used the non-toxic acrylics for this. With the acrylics, a hair dryer can shorten the time between coats. I would not use the hair dryer with any paints that are solvent based.

Once the lure is all white, dip the end of the lure in the red paint.

The last cool bit of the painting is the eyes. There is a great trick for painting the eyes. I use a small piece of a dowel and a small nail. You dip the dowel (or a larger nail) in white paint and make a dot where you want the eye. Let this dry and dip the smaller nail into black paint and put a dot for the pupil.

Here is a pic of the two lures after the painting is done and I have clear coated them. You can use several coats of clear spray paint or polyurethane to get that nice shiny look and help the lures last longer. Professional lure makers use a two part epoxy to coat their lures but that is certainly not necessary. I sometimes coat mine in Devcon 2 ton epoxy I get at the hardware store.

The last step is to put on the hooks. Poke a small starter hole about 1/3 of the way back from the head on the bottom of the lure. Put another screw eye in this hole. To hang the hooks, I like to use split rings. You can get them in the fishing section of sporting goods stores. These rings let you change the hooks easily if you break them. The split rings are a little fussy to get on. You can buy special split ring pliers (also in the sporting goods section) or you can just pry them open with the tiny screw driver that comes in a glasses repair kit. I will say, if you are going to do several lures – spring for the split ring pliers. They make it easier to get the hooks on without getting poked.

Here is the finished lure.

Good luck and let me know how they turn out!

Jim